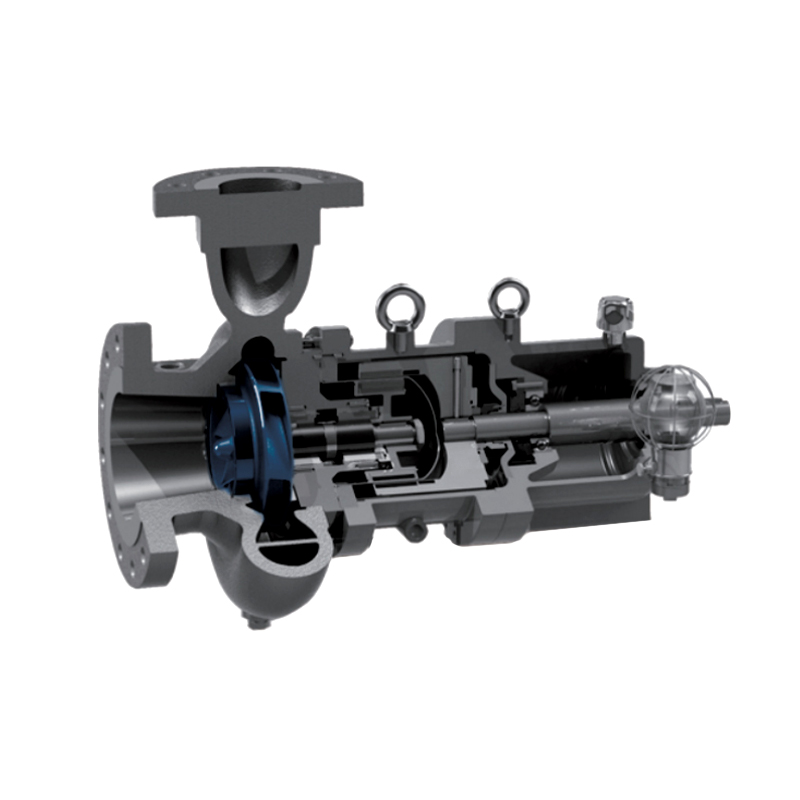

The Industrial Metering Diaphragm Pump has established itself as the gold standard for these applications. Unlike centrifugal or rotary lobe pumps, its unique hermetic design eliminates the most common failure points in fluid handling. Here is a technical breakdown of why this pump architecture is the safest choice for corrosive media.

1. Leak-Free Hermetic Sealing (The Seal-less Design)

The primary reason an Industrial Metering Diaphragm Pump is considered the safest option is its seal-less construction.

1.1 Elimination of Mechanical Seals

Traditional pumps rely on mechanical seals or packing to prevent fluid from leaking along the rotating shaft. In corrosive environments, these seals are prone to chemical attack, thermal degradation, and eventual failure, leading to hazardous leaks.

- The Diaphragm Barrier: In a metering diaphragm pump, the fluid is completely isolated from the drive mechanism by a flexible membrane (the diaphragm).

- Static Sealing: The only seals present are static gaskets or O-rings at the pump head, which are far more reliable and easier to maintain than dynamic mechanical seals.

2. Advanced Material Compatibility

Durability in corrosive service is heavily dependent on the materials in contact with the fluid (the “wetted end”).

2.1 Engineered Polymers and Alloys

Industrial metering pumps offer a wide array of chemically resistant materials:

- PTFE (Teflon): Most diaphragms are either made of solid PTFE or have a PTFE face. PTFE is virtually inert to almost all industrial chemicals.

- PVDF and PP: Pump heads can be machined from Polyvinylidene Fluoride (PVDF) or Polypropylene for handling strong acids.

- Exotic Alloys: For high-pressure corrosive applications, wetted parts can be crafted from Hastelloy C, Titanium, or 316L Stainless Steel.

2.2 Multi-Layer Diaphragm Technology

Modern high-safety pumps utilize a Double Diaphragm System . Two separate membranes are sandwiched together. If the primary diaphragm ruptures due to chemical wear, the secondary diaphragm maintains the seal, preventing the chemical from entering the pump’s gearbox or the atmosphere.

3. High-Precision Dosing and Safety Control

Safety isn’t just about preventing leaks; it’s also about preventing process overruns or chemical imbalances.

3.1 Accuracy and Repeatability

An Industrial Metering Diaphragm Pump is a positive-displacement pump. It delivers a specific volume of fluid per stroke with an accuracy of ±1% .

- Prevention of Exothermic Reactions: In applications like pH neutralization, adding too much acid or base too quickly can cause a violent thermal reaction. The precise control offered by these pumps ensures that chemical delivery is metered exactly to the process requirement.

3.2 Integrated Leak Detection

Many industrial-grade units are equipped with pressure sensors between the double diaphragms. If a breach occurs, the sensor triggers an alarm or shuts down the pump immediately, allowing for “fail-safe” operation before any hazardous material escapes.

4. Performance Matrix: Diaphragm vs. Other Pump Types

| Safety Feature | Diaphragm Pump | Centrifugal Pump | Gear Pump |

|---|---|---|---|

| Seal Type | Hermetic (Static) | Mechanical (Dynamic) | Mechanical (Dynamic) |

| Dry Run Ability | Excellent | Poor (Seal Damage) | Moderate |

| Corrosion Resistance | Superior (PTFE focus) | Variable | Moderate (Metal focus) |

| Precision | High (Metering) | Low | Moderate |

| Secondary Containment | Available (Double Diaphragm) | Rare | None |

5. Maintenance Safety and Environmental Compliance

From a regulatory standpoint (EPA, OSHA, or ECHA), the use of an Industrial Metering Diaphragm Pump simplifies compliance.

- Emission Control: Because there is no shaft seal, there are no fugitive emissions. This is critical when handling Volatile Organic Compounds (VOCs) or toxic gases in liquid form.

- Safe Maintenance: Modern “plug-and-play” liquid ends allow technicians to replace the diaphragm without being exposed to the residual chemicals inside the gearbox, reducing the risk of workplace accidents.

6. A “Zero-Leak” Future

When handling corrosive chemicals, the stakes are high. A single leak can result in equipment damage, environmental fines, or serious injury. By choosing an Industrial Metering Diaphragm Pump , facilities leverage a design that prioritizes isolation and precision. With the combination of PTFE-faced diaphragms, double-containment systems, and high-accuracy dosing, it remains the most robust defense against the challenges of aggressive fluid handling.

7. FAQ: Frequently Asked Questions

Q1: Can these pumps handle abrasive slurries as well as corrosive acids?

A: Yes. Because the diaphragm moves with a reciprocating motion rather than a high-speed rotation, it is much less susceptible to the abrasive wear that destroys the tight tolerances of gear or centrifugal pumps.

Q2: What is the lifespan of a PTFE diaphragm in corrosive service?

A: Depending on the stroke frequency and chemical concentration, a high-quality diaphragm is typically rated for 20,000 to 50,000 operating hours . However, an annual inspection is recommended for safety.

Q3: Does a metering pump require a relief valve?

A: Yes. Because it is a positive displacement pump, it will continue to build pressure if the discharge line is blocked. A pressure relief valve (PRV) is an essential safety component to prevent pipe bursts.

8. References

- API Standard 675: Positive Displacement Pumps - Reciprocating.

- Hydraulic Institute (HI) Standards for Metering Pumps.

- Chemical Resistance Guide for Metals and Polymers, NACE International.

- OSHA Guidelines for Handling Hazardous and Corrosive Materials.

.jpg)

TOP

TOP