When it comes to selecting the right pump for your industrial application, the decision between an industrial magnetic pump and a traditional pump can significantly impact operational efficiency, safety, and long-term costs. Industrial magnetic pumps offer several key benefits that make them an appealing choice in comparison to traditional pumps.

1. Enhanced Safety Features

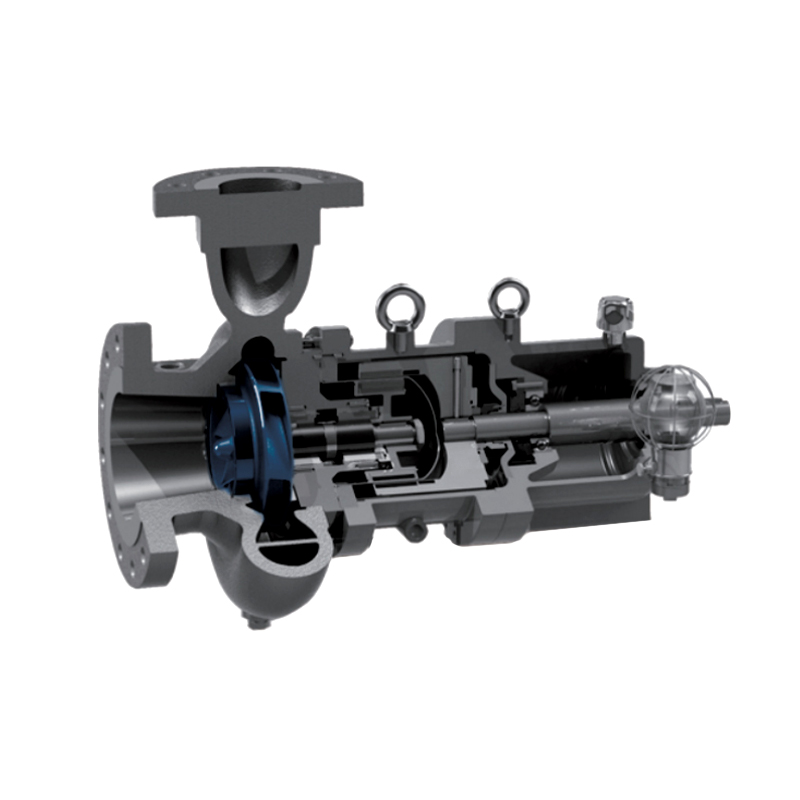

One of the biggest advantages of industrial magnetic pumps is their sealless design , which eliminates the need for shaft seals—common in traditional pumps. In traditional pumps, seals can wear out over time, leading to leaks of hazardous or corrosive fluids. These leaks pose significant safety risks to workers and the environment.

With a magnetic pump , the liquid is sealed within the pump casing, and there is no mechanical seal or dynamic seal involved in the pumping process. The motor is connected to the impeller via a magnetic coupling, allowing the pump to operate without any physical contact between the pump components and the liquid being pumped.

This sealless design prevents:

- Leakage of hazardous chemicals

- Contamination of the pumped liquid

- Potential for spills or environmental damage

For industries handling toxic, flammable, or expensive liquids (like chemicals, pharmaceuticals, or food processing), the safety provided by magnetic pumps can be crucial.

2. Reduced Maintenance Costs

Maintenance of traditional pumps can be costly and time-consuming. Traditional pumps rely on mechanical seals, bearings, and other moving parts that degrade over time. These components need regular inspection, lubrication, and eventual replacement, leading to higher operational costs and more downtime.

In contrast, magnetic pumps have fewer moving parts and are sealless , which means less wear and tear. The absence of mechanical seals means you won’t face the high costs associated with seal replacements, repairs, or maintenance downtime.

Here’s a comparison of maintenance requirements for traditional pumps versus magnetic pumps:

| Maintenance Task | Traditional Pump | Magnetic Pump |

|---|---|---|

| Seal replacements | Frequent (every 1-2 years) | None |

| Bearing lubrication | Required | Not necessary |

| Frequency of inspections | High | Low |

| Downtime due to maintenance | High | Low |

| Overall maintenance cost | High | Low |

This reduction in maintenance time and cost can help increase the overall profitability and efficiency of your operations.

3. Higher Efficiency and Reliability

Magnetic pumps are designed to offer higher efficiency than traditional pumps. The lack of seals and packing means that there is less energy loss during the pumping process. In traditional pumps, the mechanical seals and friction from moving parts result in energy dissipation, making them less efficient.

Magnetic pumps use a direct magnetic coupling that transmits power from the motor to the impeller with minimal friction. As a result, they operate more efficiently, reducing energy consumption and improving system reliability.

The reliability of magnetic pumps is especially evident in continuous processes where downtime can be costly. Magnetic pumps are built to last longer with fewer parts that are susceptible to wear, making them a reliable option for industries that demand 24/7 operation.

4. Handling of Viscous Fluids

Magnetic pumps are particularly effective at handling viscous fluids , such as oils, slurries, and thick chemicals. Traditional pumps often struggle with these types of fluids, as they can clog or experience excessive wear due to the internal friction of the fluid.

Because magnetic pumps operate without mechanical seals or gaskets, they are less prone to clogs or breakdowns when pumping viscous fluids. The simplicity of the internal structure also allows magnetic pumps to handle slurries and viscous liquids more efficiently, making them ideal for industries such as:

- Chemical manufacturing

- Food and beverage

- Oil and gas

- Mining and slurry processing

The ability to handle a wide range of fluids without additional modifications or risk of failure makes magnetic pumps a versatile choice for challenging applications.

5. Preventing Contamination

In industries such as pharmaceuticals , biotechnology , and food processing , contamination control is paramount. Traditional pumps, with their mechanical seals, can allow tiny amounts of contaminants into the system when seals degrade. These contaminants can compromise the quality of the product, leading to expensive recalls or loss of consumer trust.

Magnetic pumps, with their sealless design , prevent the risk of contamination. Since there are no physical connections to the pumped liquid, the risk of contamination is greatly reduced . This is particularly beneficial when handling high-purity or sensitive liquids.

For example, in the pharmaceutical industry, even the smallest trace of contamination can ruin an entire batch of medication. Magnetic pumps ensure that the liquid remains uncontaminated, which is crucial for maintaining product integrity.

6. Better for High-Pressure Systems

Magnetic pumps are designed to handle high-pressure applications with ease. Traditional pumps may require multiple seals and additional supports to maintain proper pressure, which increases the complexity of the system and the chances of failure. These seals can also degrade under high pressure, causing leaks or inefficiencies.

In contrast, magnetic pumps are engineered to handle high pressures without relying on seals. The magnetic coupling allows the pump to maintain consistent pressure without the need for complicated seals or packing materials.

For example, in chemical processing or oil and gas applications, where fluids are often pumped at high pressures, magnetic pumps are a superior option because they maintain performance without compromising safety or efficiency.

7. Cost-Effectiveness in the Long Run

Although the initial cost of an industrial magnetic pump may be higher than that of a traditional pump, the long-term savings in maintenance , downtime , and energy efficiency often make magnetic pumps a more cost-effective solution .

By eliminating frequent seal replacements and reducing the need for maintenance staff, magnetic pumps provide a better return on investment (ROI) over time. Additionally, their energy efficiency leads to lower operational costs, further enhancing cost-effectiveness.

Consider the following key factors that contribute to the overall cost-effectiveness of magnetic pumps:

- Lower maintenance costs (no seals to replace)

- Energy savings (more efficient operation)

- Longer lifespan (fewer breakdowns)

In many cases, the total cost of ownership for a magnetic pump is lower over its operational life compared to traditional pumps.

8. Energy Savings

Energy consumption is a significant factor in pump selection, especially for large-scale industrial applications. Traditional pumps often lose energy due to the friction from mechanical seals and bearings. Magnetic pumps, on the other hand, are more energy-efficient because their sealless design minimizes friction and power loss.

Here’s how energy savings stack up with magnetic pumps:

- Lower energy consumption due to fewer moving parts

- Higher operational efficiency , especially in continuous-flow applications

- Reduced load on the motor , which prolongs motor life

By switching to magnetic pumps, many industries experience a reduction in energy usage, leading to lower operational costs and a smaller environmental footprint.

9. Versatility Across Applications

Magnetic pumps are highly versatile and can be used in a variety of industries. From chemical processing to water treatment , their design allows them to handle a wide range of liquids and operational conditions.

Some industries where magnetic pumps excel include:

- Chemical manufacturing (for pumping corrosive or hazardous chemicals)

- Food and beverage (for pumping liquids without contamination)

- Pharmaceuticals (for maintaining purity and avoiding contamination)

- Water treatment (for handling abrasive and non-viscous fluids)

The versatility of magnetic pumps makes them an attractive option for industries with diverse pumping needs.

10. Eco-Friendly Operations

Finally, magnetic pumps contribute to greener operations . Since they have no mechanical seals that require lubricants or sealing agents, they reduce the consumption of materials that can harm the environment. Additionally, the efficiency of magnetic pumps results in lower energy usage, which reduces the carbon footprint of your operation.

Magnetic pumps help industries meet environmental regulations by reducing the risk of spills, leaks, and contamination. This makes them an excellent choice for companies looking to improve their sustainability efforts and reduce their environmental impact.

.jpg)

TOP

TOP